0

You have 0 items in your cart

- Home

- Tooling & Automation

- Companies & Capabilities

- Segen Quick Change

- News

- Resources

- About Us

- Contact Us

A leading North American designer and manufacturer of commercial and residential faucets with joint ventures in Canada, Asia, Mexico, and South America and estimated revenue of $400M and over 1000 employees. This project was for one of the company’s North Carolina manufacturing facilities.

The challenge was to design and build an automated system capable of assembling and testing 13 different types of bath faucet assemblies with a cycle time of nine seconds. The system would allow small production runs as well as mass production runs with a simple changeover

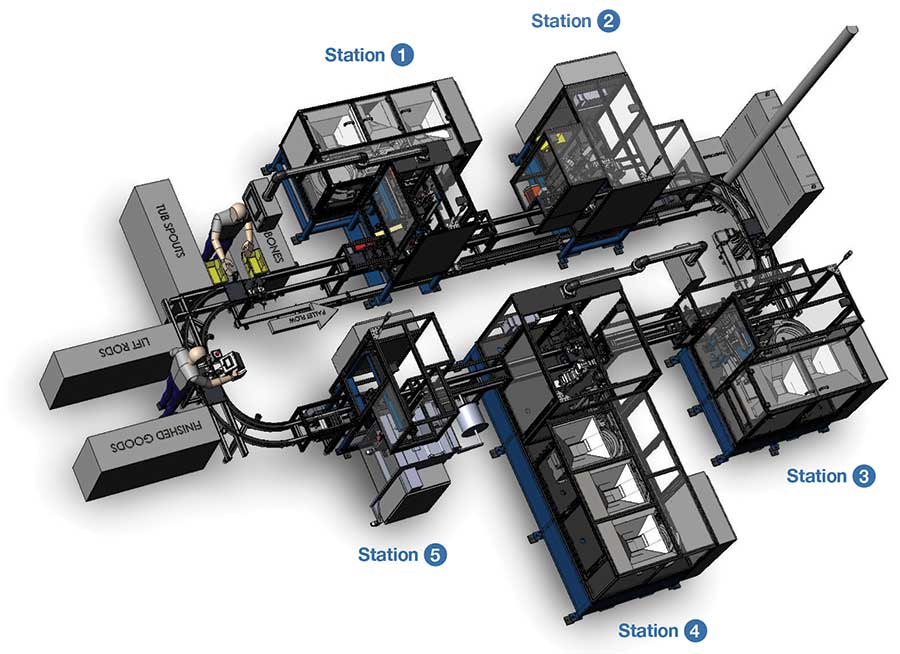

Utilizing a pallet conveying system equipped with RFID, Alpha Integration, a Tooling Tech Group company and automation specialist, introduced individual part pallets through each assembly cell where specific part processes were performed, inspected and verified for accuracy. The following process was performed in each station, providing a fully assembled and quality verified bath faucet.

A screw and two separate formed metal parts were fed via a feeder bowl, mated together and the screw was driven to a specific torque and angle. These parts were then mated into a plastic feeder that conveys water through the spout once installed.

Plastic feeder is picked from the conveyor pallet using a 6-axis robot and placed into a cell that rotates the feeder while applying a sealant to the threads of the feeder. The feeder is then screwed into the bath faucet assembly using a torque and angle monitoring system, ensuring the proper depth and force have been reached.

A metal shaft and knob are fed via feeder bowls where they are then mated and pressed together forming a completed assembly that is then placed into the end of the spout.

A plastic housing and seal are fed via a feeder bowl where they are then picked and placed into one another, forming a completed seal for the bath faucet assembly/shower selector. A 6-axis robot then picks this assembly, inserts it into the end of the bath faucet assembly while also engaging the previously mated metal shaft and knob into the spout, creating a fully-assembled and working unit.

Bath faucet assemblies are then picked and placed into a bagging system where each assembly is sealed into its own bag and prepared for shipment.

For more information on Tooling Tech Group’s capabilities, call 231-400-4884.

Founded in 1982, the Tooling Tech Group has grown organically, and through acquisition, to become the largest tooling provider in the United States with 650+ employees, 4 divisions and over 1 million square feet of manufacturing space across four states.

The depth and breadth of our capabilities is achieved through the combined experience of our company units, with each of these companies being in business for 30+ years, providing both extensive industry experience and financial stability that you can rely upon.

Our unique differentiator is the ability to provide all tooling services from design to engineering to simulation to machining to fabrication to try-out all within one company. This single source ability can help to streamline your business operations and simplify your life. As a vertically integrated company, we maintain tight control over quality and can provide custom services to meet your total program needs. We take full responsibility for quality, delivery, and cost management of each project starting at concept through “on time, every time” delivery.

Together, we have earned a reputation for manufacturing the highest quality tooling for casting, molding, forging and stamping. We also produce secondary automated solutions to transform parts into assemblies and functional products used around the world. We accomplish this by applying our expertise along with the latest technology, techniques, and CNC equipment to design, engineer, manufacture and test your tooling.