0

You have 0 items in your cart

- Home

- Tooling & Automation

- Companies & Capabilities

- Segen Quick Change

- News

- Resources

- About Us

- Contact Us

Recognized as the largest heavy-gauge industrial thermoformer in North America, Kruger Family Industries (KFI) has a 45-year history through its two Portage, Wisconsin-based brands – TriEnda – known for producing pallets, dunnage and material handling material, and Penda, focused on truck bed liners and other automotive components. Additionally, KFI has two factories in Mexico. Altogether there are about 1,000 employees and nearly 1,000,000 sq. ft. of manufacturing space housing 39 thermoforming machines, each with a forming area of 64 sq. ft.

During March 2020, at the start of Covid, automotive plants were shutting down indefinitely and KFI wanted to quickly develop a new revenue stream. Management sent a note to the engineering group, challenging them to think about what the company could make to serve the medical industry and asking them to bring ideas in within a weekend’s time, considering capability, time to market, efficient price point and scalability. Hospital beds became the company’s focus as they already made fold-down beds for the Class A truck industry, providing them with existing FEA modeling regarding the stress and deflection points for when people sleep in thermoformed beds.

Once this manufacturing decision was made, KFI turned to Tooling Technology in Ft. Loramie, Ohio, a Tooling Tech Group (TTG) company and long-time supplier of thermoforming tools to both Penda and TriEnda for assistance on this critical project.

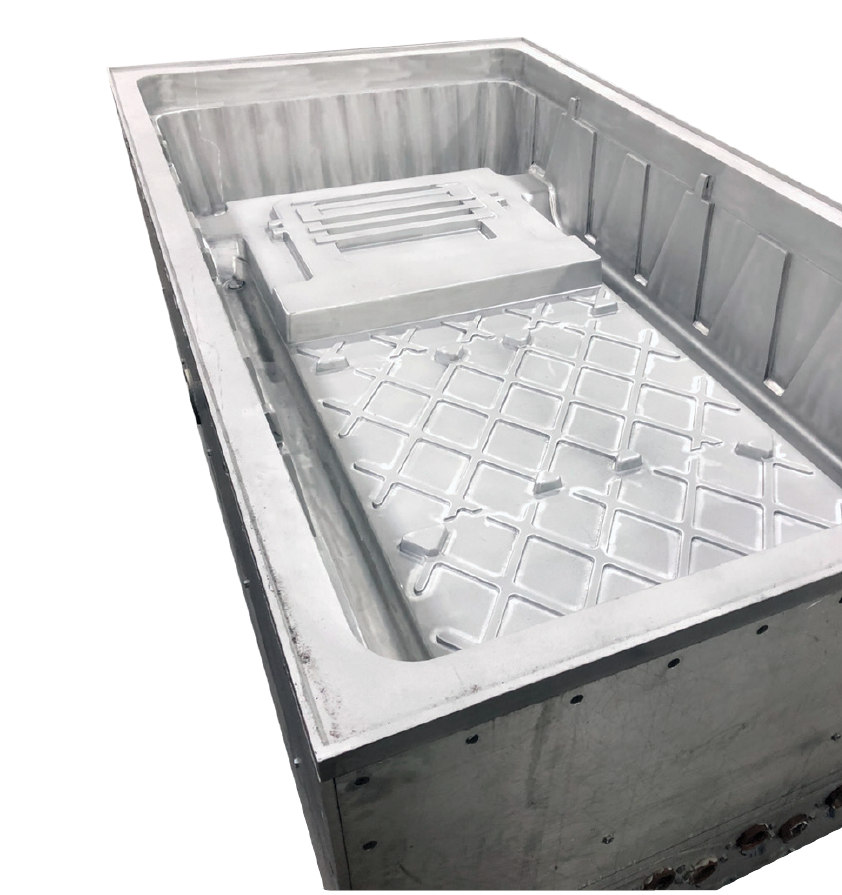

Emergency & Disaster Relief Bed back support

Emergency & Disaster Relief Bed base

Producing molds of this size normally takes a five-to-six-week turnaround. By pulling together its resources and leveraging its vertical integration, TTG was able to go from design to finished tool in less than the customer-requested two-week delivery actually supplying four sets of tools (two beds and two backrests molds) within 10 days.

In addition to the original tool set, TTG produced three additional bed base tools and two more back rest tools for thermoforming the beds. All of this was accomplished without compromising delivery schedules of other customer projects at the facility.

TTG’s vertical integration allowed four (4) sets of tooling to be produced within 10 days.

Since 2020, much business has returned to something close to ‘normal’. But, as quoted by KFI personnel:

For more information on Tooling Tech Group’s capabilities, call 231-400-4884.

Founded in 1982, the Tooling Tech Group has grown organically, and through acquisition, to become the largest tooling provider in the United States with 650+ employees, 4 divisions and over 1 million square feet of manufacturing space across four states.

The depth and breadth of our capabilities is achieved through the combined experience of our company units, with each of these companies being in business for 30+ years, providing both extensive industry experience and financial stability that you can rely upon.

Our unique differentiator is the ability to provide all tooling services from design to engineering to simulation to machining to fabrication to try-out all within one company. This single source ability can help to streamline your business operations and simplify your life. As a vertically integrated company, we maintain tight control over quality and can provide custom services to meet your total program needs. We take full responsibility for quality, delivery, and cost management of each project starting at concept through “on time, every time” delivery.

Together, we have earned a reputation for manufacturing the highest quality tooling for casting, molding, forging and stamping. We also produce secondary automated solutions to transform parts into assemblies and functional products used around the world. We accomplish this by applying our expertise along with the latest technology, techniques, and CNC equipment to design, engineer, manufacture and test your tooling.