0

You have 0 items in your cart

- Home

- Tooling & Automation

- Companies & Capabilities

- Segen Quick Change

- News

- Resources

- About Us

- Contact Us

TriEnda is a global manufacturer of thermoformed packaging, automotive and material handling solutions in Portage, Wisconsin. Together with sister company Penda and their parent, Kruger Family Industries (KFI), the group employs more than 800 associates in four locations across North America and enjoys a nearly five-decades-long reputation as a leader in the thermoforming industry.

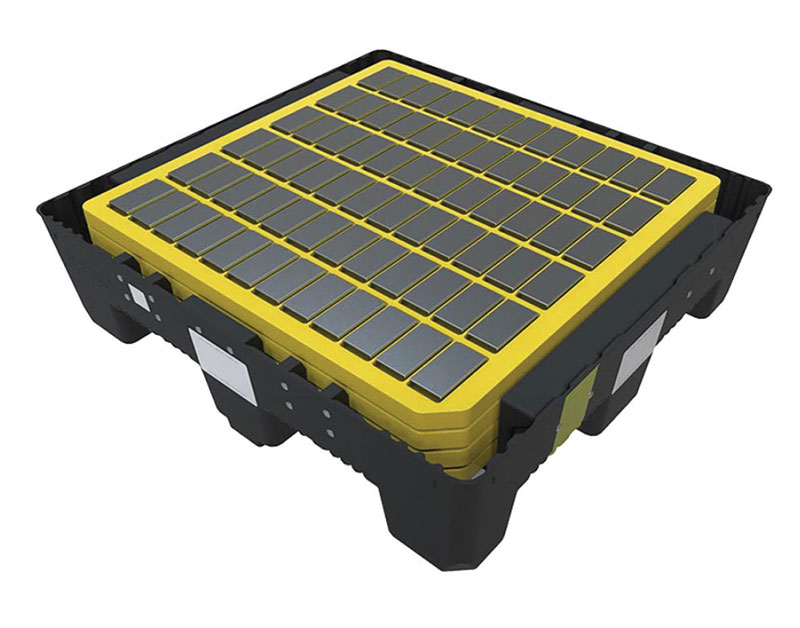

A major North American automotive supplier asked TriEnda to manufacture a reusable shipping container for the battery packs used to power battery electric vehicles (BEVs), one that would meet demanding UN criteria for shipment of dangerous goods. Constructed of ABS (Acrylonitrile Butadiene Styrene) and steel substructure for strength, the container must support robotic loading and unloading of the 37 compartmentalized trays within, each carrying 16 relatively soft, liquid-filled battery cells for a total of 592 per container.

Closed Case

The customer originally conceived that the battery trays be injection-molded. However, with a height tolerance of +/-0.013″ per tray and the fact that only a few injection mold machines in the entire country had sufficient tonnage for that size workpiece, TriEnda soon realized the battery trays would be extremely difficult to manufacture as specified. Instead, it was decided to use the thermoforming process, even though ABS plastic is much more difficult to thermoform than the HDPE used elsewhere in the container. Undeterred, TriEnda personnel built a prototype mold, tested the process, and after customer approval, turned to longtime supplier Tooling Tech Group (TTG) of Ft. Loramie, Ohio for the production tools.

Open Case

Founded in 1982, the Tooling Tech Group has grown organically, and through acquisition, to become the largest tooling provider in the United States with 650+ employees, 4 divisions and over 1 million square feet of manufacturing space across four states.

The depth and breadth of our capabilities is achieved through the combined experience of our company units, with each of these companies being in business for 30+ years, providing both extensive industry experience and financial stability that you can rely upon.

Our unique differentiator is the ability to provide all tooling services from design to engineering to simulation to machining to fabrication to try-out all within one company. This single source ability can help to streamline your business operations and simplify your life. As a vertically integrated company, we maintain tight control over quality and can provide custom services to meet your total program needs. We take full responsibility for quality, delivery, and cost management of each project starting at concept through “on time, every time” delivery.

Together, we have earned a reputation for manufacturing the highest quality tooling for casting, molding, forging and stamping. We also produce secondary automated solutions to transform parts into assemblies and functional products used around the world. We accomplish this by applying our expertise along with the latest technology, techniques, and CNC equipment to design, engineer, manufacture and test your tooling.