0

You have 0 items in your cart

- Home

- Tooling & Automation

- Companies & Capabilities

- Segen Quick Change

- News

- Resources

- About Us

- Contact Us

Speeds Set Up in a Variety of Processes and Applications

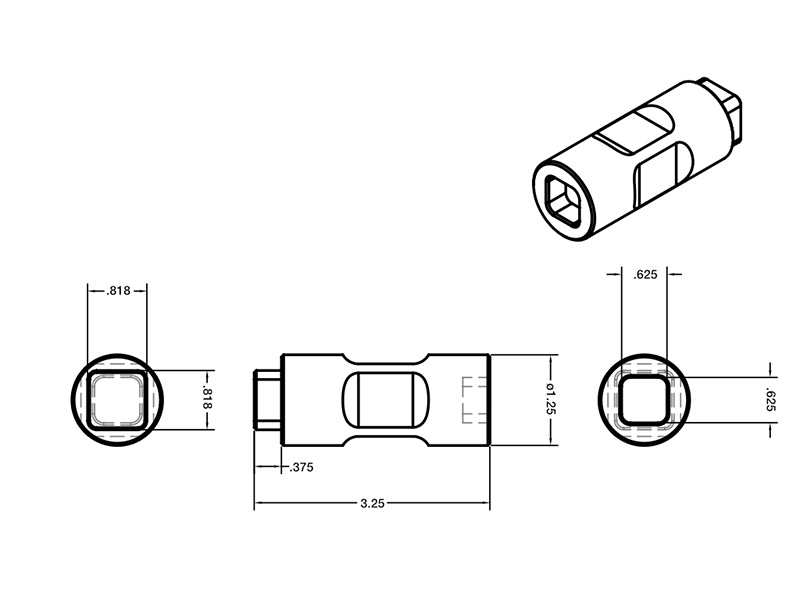

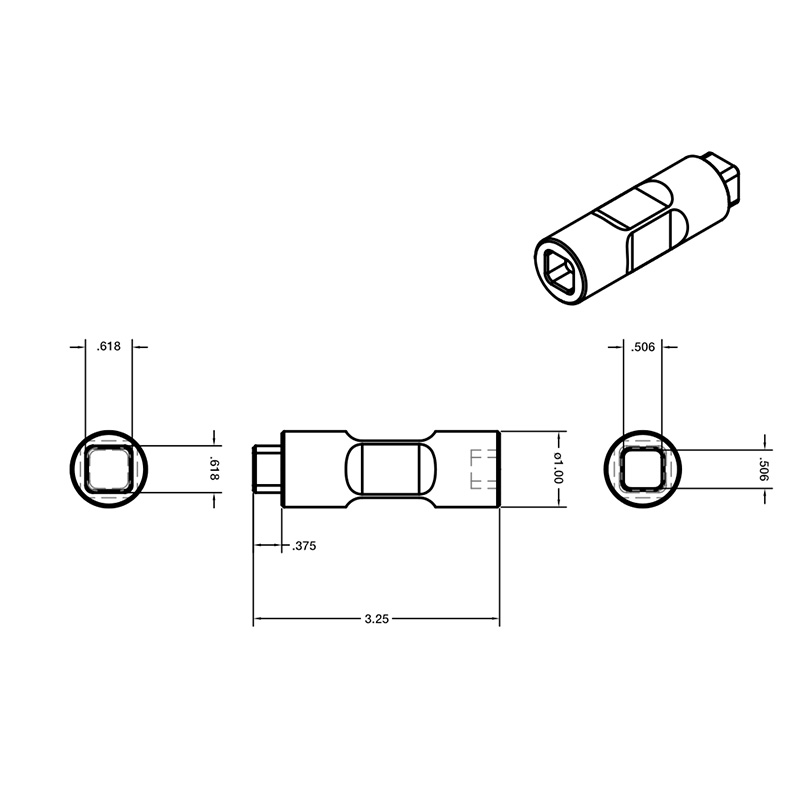

Tooling Tech Group (TTG) has added sockets to its family of Segen Quick Change devices, designed to complement the existing series of knobs and cylinders to speed setup. The sockets are available in three sizes, each designed to work with a standard Segen knob size including the PD250 micro knobs, the 375 mini knobs and the 438 knobs. These sockets mate with standard 3/8” socket drives— so no special tooling is required.

The Segen Quick Change system replaces old-fashioned nuts, bolts, fasteners, and hand tools, to significantly reduce the time wasted on industrial setups, changeovers, work holding, tool holding, clamping, fixturing, and alignment. These strong, precise, and reliable cylinders and mating knobs can reduce downtime, improve quality, eliminate waste, enhance efficiency, and increase overall profitability.

Although the application of these devices is numerous, they are especially well-suited to thermoforming and injection mold tooling, robotic fixturing and end-of-arm tooling, CNC machining, and ultrasonic welding fixtures.

Full information can be found at Segen Quick Change System, as well as being available through the company’s online store or by calling 231-400-4884.

Fill out the form for more information and we will get back to you.

Request a Quote