0

You have 0 items in your cart

- Home

- Tooling & Automation

- Companies & Capabilities

- Segen Quick Change

- News

- Resources

- About Us

- Contact Us

Majestic Industries can serve as a single source for your stamping die and production needs. Specializing in the design and build of progressive and transfer die tooling, we employ advanced processes to handle every step of the die build, from concept through finished product and die try-out on our selection of presses. In addition to stamping dies, our Die Cast Division engineers and builds die cast tooling for complex aluminum and magnesium programs. We are also experts in designing dies to run mid-to-high-volume production of high-strength, dual-phase steel stampings.

Majestic offers you a one-stop shop for your stamping needs, helping to simplify your sourcing. We provide everything needed for die design, manufacture and repair, as well as being capable of handling your production stamping needs, including emergency work.

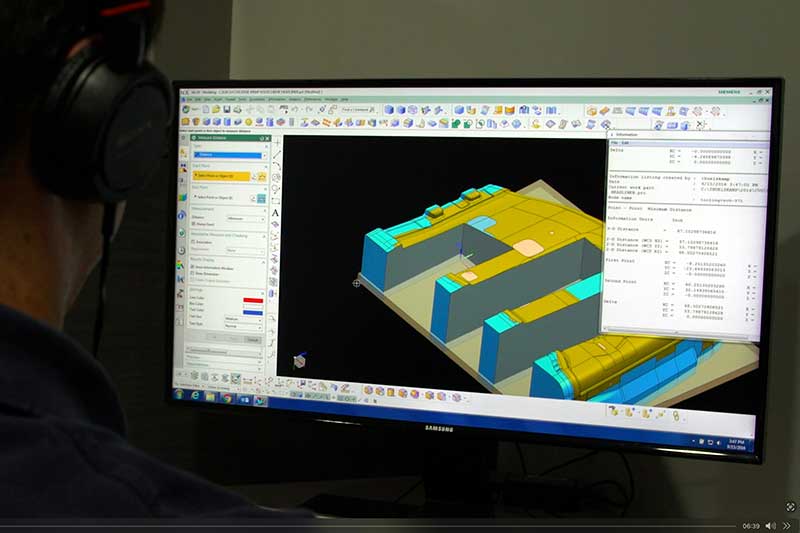

Majestic has a full engineering team to provide tool and die design, CNC-machined die components, die details sourcing, product and process simulation, and other related services.

We have expertise in designing dies for stamping of advanced steel with higher strength and work-hardening tendencies during forming.

We have five stamping presses ranging in size from 800 tons to 2,750 tons ready to take on offload work.

When it comes to automotive applications, Majestic’s capability encompasses building dies for every stamped structural component on a vehicle. That includes all powertrain and propulsion styles – internal combustion engine (ICE), electric vehicles (EV) and hydrogen fuel cells. Additionally, our services include secondary manufacturing services, such as incorporating fasteners into the finished stamped part, as well as in-die and post-process staking and welding of nuts and studs.

Majestic is experienced in design and build of stamping dies for a variety of structural parts used in the heavy truck industry – chassis, frame, suspension components, and more. Additionally, given our range of stamping presses, we can run production of large parts.

Majestic is ready for the growing use of alternative energy sources. We provide stamping dies for structural parts, such as racks, frames, and enclosures for the renewable energy industry, (solar, wind, hydro) industry and energy storage. The quality of our tooling enables production of identical parts with minimal variation, leading to cost-effective manufacturing processes.

At Majestic, our facilities are stocked with state-of-the art equipment run by highly skilled machine operators to ensure we deliver to you the highest quality dies.

Click on an item below to view details.