0

You have 0 items in your cart

- Home

- Tooling & Automation

- Companies & Capabilities

- Segen Quick Change

- News

- Resources

- About Us

- Contact Us

360 Yield Center designs and manufactures innovative agricultural products to enhance crop production. They work to answer the industry’s biggest question, “How can we prevent nature and inefficiencies from negatively impacting a farm’s season?”. Their team is focused on capturing more yield by refining the traditional growing cycle through more timely watering, improved nutrient placement, and focused chemical application.

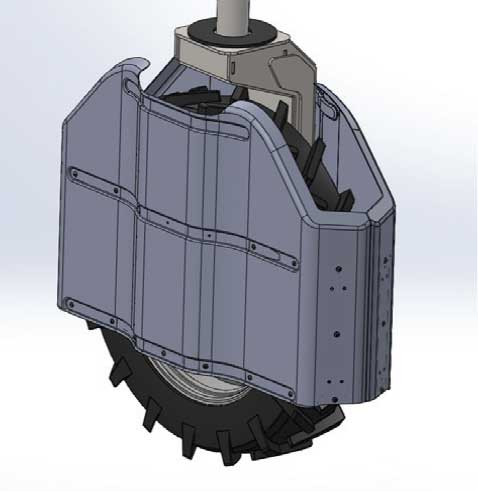

The customer wanted to develop a shield for the wheels of its existing 360 RAIN product, an unmanned irrigation machine. Given the product dimensions and production volume, they determined that thermoforming would be the best manufacturing process. However, since this was the company’s first vacuum thermoformed part, their internal staff did not have the design knowledge or forming capability in house to produce these parts. Nor did they have any qualified vendors in their supply chain to help on this project.

The 360 RAIN delivers bands of water, nutrients, and fungicides directly to the base of plants.

Tooling Tech was able to provide a true “one-stop-shop” experience to 360 Yield Center for the complete product development process. Starting from the initial part and tool design, to the actual tool build, to finding and qualifying an outside forming vendor, communicating timing and logistics with the vendor, and shipment of final parts to the customer—we handled every step.

Newly-designed component to shield the wheels on the 360 RAIN.

Samples of the new wheel shield thermoformed part.

Founded in 1982, the Tooling Tech Group has grown organically, and through acquisition, to become the largest tooling provider in the United States with 650+ employees, 4 divisions and over 1 million square feet of manufacturing space across four states.

The depth and breadth of our capabilities is achieved through the combined experience of our company units, with each of these companies being in business for 30+ years, providing both extensive industry experience and financial stability that you can rely upon.

Our unique differentiator is the ability to provide all tooling services from design to engineering to simulation to machining to fabrication to try-out all within one company. This single source ability can help to streamline your business operations and simplify your life. As a vertically integrated company, we maintain tight control over quality and can provide custom services to meet your total program needs. We take full responsibility for quality, delivery, and cost management of each project starting at concept through “on time, every time” delivery.

Together, we have earned a reputation for manufacturing the highest quality tooling for casting, molding, forging and stamping. We also produce secondary automated solutions to transform parts into assemblies and functional products used around the world. We accomplish this by applying our expertise along with the latest technology, techniques, and CNC equipment to design, engineer, manufacture and test your tooling.