0

You have 0 items in your cart

- Home

- Tooling & Automation

- Companies & Capabilities

- Segen Quick Change

- News

- Resources

- About Us

- Contact Us

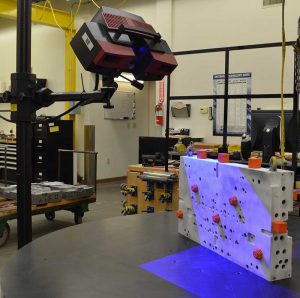

Sept. 19, 2019 – G.H. Tool & Mold, a Tooling Tech Group company and a supplier of die cast tooling and machining services, has expanded its capacity and capability by adding a second GOM ATOS Triple Scan high-resolution, 3D optical digitizer for automated measuring and inspection of its casting dies.

Sept. 19, 2019 – G.H. Tool & Mold, a Tooling Tech Group company and a supplier of die cast tooling and machining services, has expanded its capacity and capability by adding a second GOM ATOS Triple Scan high-resolution, 3D optical digitizer for automated measuring and inspection of its casting dies.

“This new system will allow us to further our scanning inspection service to our Tier and OEM customers who have fully embraced this technology and are requesting it on an ever-expanding scale,” said G.H Tool’s President Dave Graves.

G.H. Tool is using the scanners to inspect new tooling as well as employing these systems to better serve its customers’ mold repair needs. The ATOS system is a highly precise and efficient tool for evaluating complex mold features, where the critical geometry may be damaged or worn from the production process. Digital scanning provides G.H. Tool the ability to make timely, clear and comprehensive repair plans for the customer.

Both of the company’s ATOS scanners are fully portable and can be deployed to customer locations. By pairing the capabilities of the blue light scanners with a recently purchased AL500 laser welder, G.H. Tool can provide state-of-the-art repair services at its multiple facilities.

The additional system will be operational in October 2019.

Fill out the form for more information and we will get back to you.

Request a Quote