0

You have 0 items in your cart

- Home

- Tooling & Automation

- Companies & Capabilities

- Segen Quick Change

- News

- Resources

- About Us

- Contact Us

Tooling Technology is a single source for complete aluminum cast and billet tooling solutions. Our capabilities go beyond tool design and build — accomplished via our in-house foundry — into tool fixtures and supporting automation. We’re able to provide complete tooling packages across a variety of plastic forming processes, simplifying your vendor sourcing.

When you partner with Tooling Technology, we’re positioned to support you with every aspect of your project. This in combination with our experienced staff, outstanding equipment and unique resources allows us to deliver the highest quality.

A key differentiator for Tooling Technology is our in-house foundry, which provides us complete control over the quality of your tooling, resulting in lower costs and faster delivery times.

Equipped with dozens of machine tools, Tooling Technology’s sweet spot is creating molds and tooling for mid- to large-size components, including sizes up to 343-in. long x 120-in. wide x 100-in. tall.

Tooling Technology is well-suited to handle large tooling programs, which are supported by our deep bench of qualified engineers and our seasoned program management team.

Tooling Technology builds molds for a wide range of products, such as interior trim and soft goods, floor carpet, floor mats, headliners, reservoirs, and ducting; including thermal acoustical products to reduce noise vibration and harshness (NVH). Every mold we design and deliver is built to meticulous standards.

We provide different mold and tooling technologies to meet just about any household or recreational need. Typical home applications include items such as shower pans, hot tubs, refrigerator liners or deck boxes. Our recreational and powersports capabilities include molds for items such as kayaks or hoods of recreational vehicles.

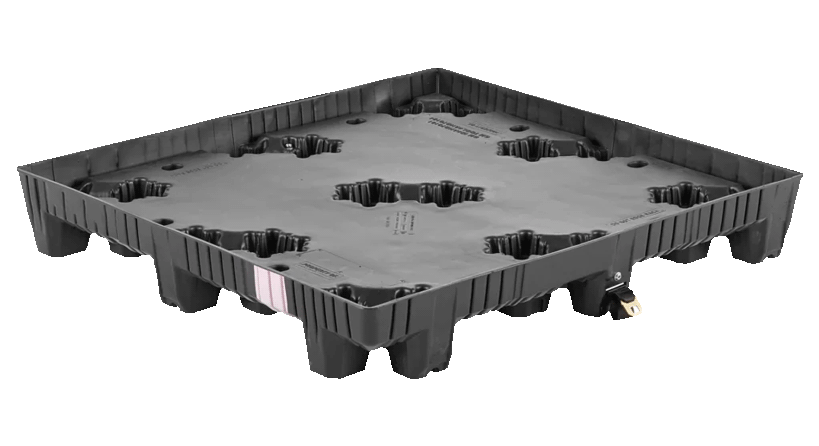

An often-underrated component of the supply chain is the importance of pallets and dunnage. Dunnage acts as a cushion buffer between the freight and the container surface. By filling the gaps between items, dunnage prevents shifting and rattling. We provide tooling for returnable dunnage to the food, courier, and automotive industries — including EV battery tray dunnage.

Tooling Technology has vast experience providing engineering and manufacturing of molds across a wide range of large vehicle applications, including interior trim and soft goods, floor carpet, floor mats, headliners, reservoirs, interior trim, and ducting.

At Tooling Technology, our facilities are stocked with state-of-the art equipment run by highly skilled machine operators to ensure we deliver to you the highest quality molds, secondary tooling and fixtures.

Click on an item below to view details.

Main Office:

100 Enterprise Drive

Fort Loramie, Ohio 45845

CMT EAST ASIA CO LTD

Suit 1002, Chuangjian Building, Shennan Blvd,

Shenzhen, China

www.cmteastasia.com

sales@cmteastasia.com

Territory: China (PRC), Hong Kong (SAR), Taiwan (ROC), Malaysia, Singapore, Thailand, Vietnam, Philippines, Laos, Cambodia, Myanmar, Brunei, Papua New Guinea, Mongolia, Japan, South Korea, India, and Indonesia