0

You have 0 items in your cart

- Home

- Tooling & Automation

- Companies & Capabilities

- Segen Quick Change

- News

- Resources

- About Us

- Contact Us

Die Cad is a global tooling service supplier, specializing in sheet metal stamping engineering. We help our customers with product and process simulation, tool and die design, special purpose machine design, die details sourcing and other related services. For three decades, we’ve built our reputation by helping our customers solve the industry’s most complex problems.

For nearly three decades, Die Cad has built a reputation for delivering reliable simulations, designs, and CNC-machined components to OEMs, Tier 1 suppliers, and tool shops. Our mission is to support our customers’ success by providing dependable engineering services and components that promptly meet their needs.

We have a full team of seasoned designers with tool shop and build experience utilizing CATIA® and NX CAD (Unigraphics) software to produce 3D designs.

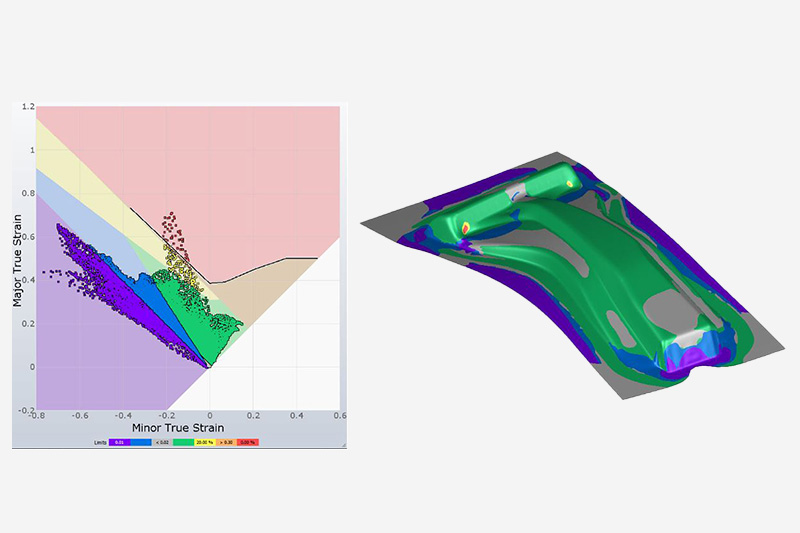

Simulation is key to the success of Die Cad tool designs. Our specialists use Auto Form software to determine feasibility, material usage, required concessions, spring back compensation and tool processing requirements.

We manage offshore suppliers to manufacture and deliver fully machined, ready-to-assemble details for your tooling needs. Our team of three in-country employees oversees project management, ensuring timely and high-quality completion. We apply the same model when partnering with domestic suppliers, offering various quoting and supply options for your full build and kit die tooling. This includes full LCC, full domestic, or a combination of both in a hybrid build.

We provide tooling engineering for a variety of motorized vehicles across various industries, including but not limited to Automotive, Agriculture, Construction equipment, Heavy Truck, Recreational and Powersports vehicles, and more.

Within the Construction industry we offer extensive design and supply experience with products like; Garage doors, Roofing Shingles, Metal Building Frames, Electrical box covers, Electrical Motor Covers, Residential and Commercial Air Conditioner and Heat Exchanger outer cabinets, and more.

We provide engineering solutions for consumer goods and appliances. Including but not limited to; Washers and Dryers, Ranges, Ovens and Cooktops, Grills, Freezers , Fans, and other HVAC components.

We support the Medical and Dental industries by offering extensive design and supply chain experience for products like Dental Exam Chairs, Hospital Beds, Veterinary Exam tables, and more.

Our team has deep experience in the engineering of new stamping dies for sheet metal applications. This experience and use of metal forming simulation software to determine part feasibility, material usage, potential part concessions, spring-back compensation, and tool processing requirements have earned us a reputation for designing dies for difficult parts with reduced tryout time after the build.

Click on an item below to view details.