0

You have 0 items in your cart

- Home

- Tooling & Automation

- Companies & Capabilities

- Segen Quick Change

- News

- Resources

- About Us

- Contact Us

Century Tool is a premier provider of high-quality compression and reaction molds for composite components across various industries and applications. As a vertically integrated company, we provide everything from design to machining to try-out under one roof. This allows us to maintain tight control over the entire process each step of the way.

Century can provide everything from design through try-out under one roof, allowing us to maintain tight control over quality and offer custom services that meet your total program needs. Our experience and competencies create synergies and streamline processes to provide a seamless and enhanced customer experience. For customers seeking complete aluminum cast, billet, or thermoforming tooling solutions, Tooling Technology provides complementary capabilities that expand the range of tooling services available.

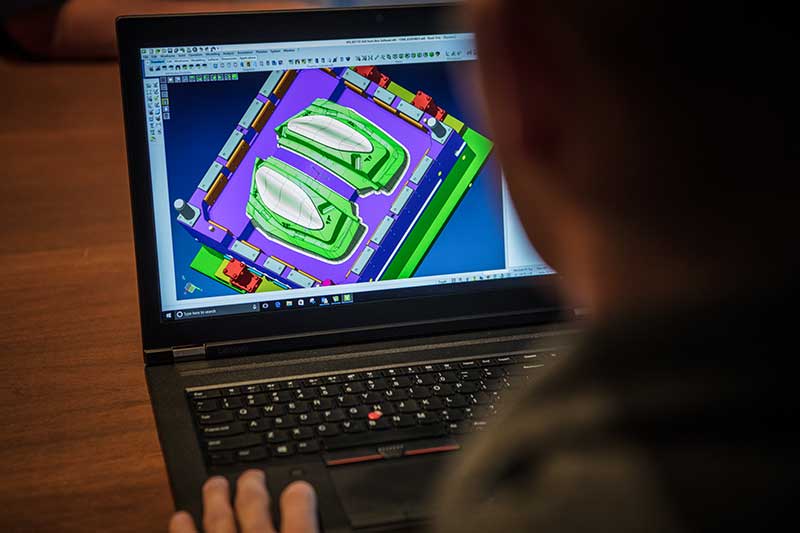

All tools and molds are designed and engineered in-house based upon customer-supplied data. We create 3D CAD models for customer review and sign-off, as well as 2D and 3D design implementation of all manufacturing processes.

A key element of our tooling solutions is the high-speed precision machining capability of our machine park. Our systems selected enable Century Tool to achieve a fine balance of speed and accuracy in the production of our tool elements.

Century offers in-house Tool Tryouts for demonstration and sample part production to ensure conformance to required standards and specifications.

When produced as a composite structure instead of a metal panel, Tooling can be reduced from a multi-tool die set to a single mold. We specialize in exterior (Class A) and structural parts that require the highest precision and surface finish. Our tools produce components ranging from Doors, Hoods and Fenders through Engine Compartment surrounds and Battery Enclosures.

We are experienced providers of tooling for a broad range of complex automotive composites including high-profile vehicles such as the Chevrolet Corvette, Ford Bronco, Jeep Wrangler, and many more. Century Tool has also supplied tooling solutions for the manufacture of delivery vehicles focused on the final mile in urban environments.

Compression molding is ideal for production of large, flat or slightly curved parts such as Class-A surfaces for exterior vehicle applications including truck cabins and hoods, roofs, and aerodynamic panels. Large components can be manufactured with minimal fiberglass degradation, yielding stronger components relative to other molding processes.

The use of lightweight materials such as composites can help vehicles on land, snow or water to achieve higher performance. In addition to reducing weight, composites are also resistant to corrosion, which makes them extremely well-suited for boat, snowmobile and UTV components.

Composites are playing an increasing role in infrastructure applications, providing durability and corrosion-resistance that contributes to long service life and low maintenance costs. Century Tool is experienced in providing tools for composite components used in underground rainwater collection, pipes, tanks, bridge decks and more.

At Century Tool, our facilities are stocked with state-of-the art equipment run by highly skilled machine operators to ensure we deliver to you the highest quality molds, dies and fixtures.

Click on an item below to view details.