0

You have 0 items in your cart

- Home

- Tooling & Automation

- Companies & Capabilities

- Segen Quick Change

- News

- Resources

- About Us

- Contact Us

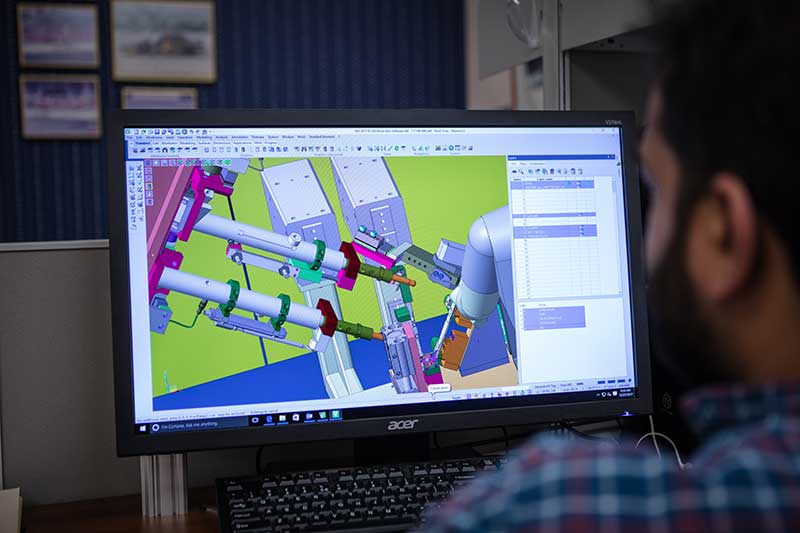

Century Automation is an experienced secondary operations automation provider to the molded parts industry, specializing in joining, trim and foam applications. From operator-assist systems to full material handling and tending, our manufacturing systems are tailored to meet each customer’s individual need.

We specialize in secondary manufacturing processes featuring streamlined operations for improved productivity while enhancing your product quality.

Century Automation is experienced developing systems inclusive of vision guidance and monitoring that employ a variety of bonding techniques including welding, bonding, fastening and lamination.

From manual load to robot-tended systems, we can provide solutions that streamline a variety of secondary processes including drilling, routing, de-gating, de-flashing, trimming and punching.

In addition to our secondary automation experience, our team also can design and build precision tooling for polyurethane foam molding applications.

Century Automation has built secondary systems for many composite structure vehicles on the road today. These systems range from a drill, route and joining cell to a floor bonding station to a weld check cell, and more. Once the primary manufacturing of a component is completed, Century can be relied upon to streamline the next process with custom automation.

With the emphasis on lightweighting, using composite structures for heavy truck body panel components continues to grow. Century Automation is experienced in providing solutions for the joining and assembly of these components, developing systems such as a single cycle bonding station for today’s and future heavy trucks.

Across multiple industries, we produce a wide range of tooling and production systems for part-joining production. We combine the right technologies to manufacture high-quality parts within customer requirements.