0

You have 0 items in your cart

- Home

- Tooling & Automation

- Companies & Capabilities

- Segen Quick Change

- News

- Resources

- About Us

- Contact Us

Tooling Tech Group creates prototypes using a variety of materials to evaluate the functionality, fit, and aesthetics of the design before committing to permanent tooling. This iterative process enables us to make necessary adjustments and improvements to ensure that the final product meets all specifications and requirements. Learn more about mold tooling, thermoforming, and compression from our Tooling Technology companies such as GH Tool & Mold and Century Tool.

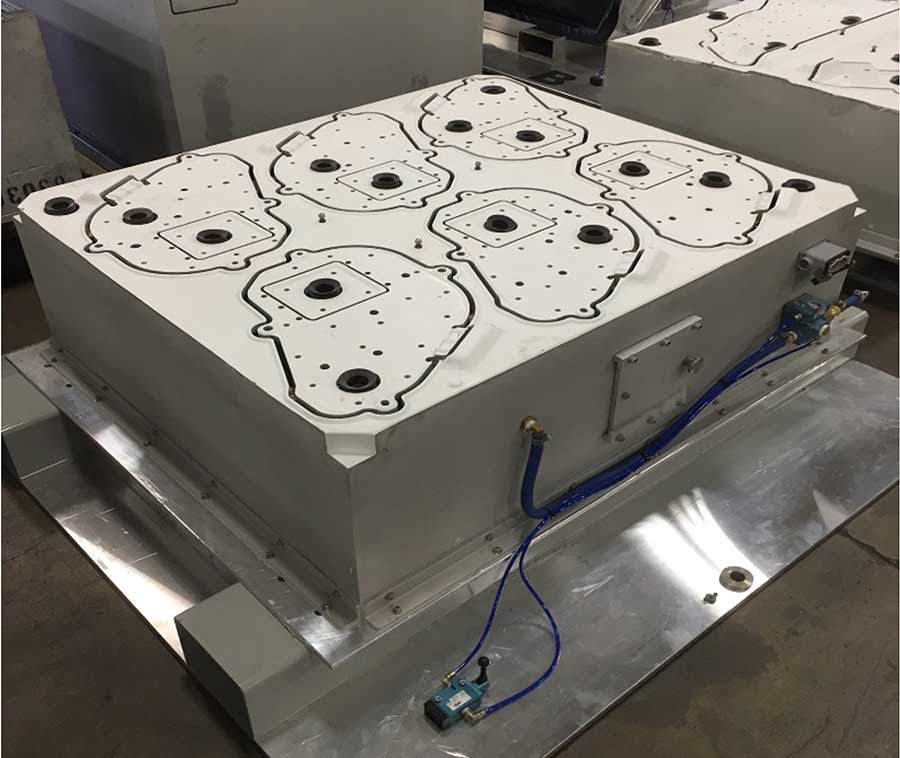

Heavy gauge cast aluminum water-cooled molds for thermoforming plays a crucial role in ensuring precise and consistent results during the manufacturing process. The water-cooling system helps regulate the mold’s temperature, preventing overheating and distortion of the final product.

Billet aluminum molds provide durability and strength, allowing for consistent performance over time. By incorporating water cooling systems within these molds, heat generated during the thermoforming process can be quickly dissipated, resulting in faster cycle times and increased productivity.

You can get your entire tooling program, including the waterjet fixtures, from Tooling Tech Group. These fixtures are designed to hold the molded parts securely in place while a high-pressure waterjet precisely trims excess material, resulting in clean and uniform edges.

Designed to hold and support parts during inspection, these fixtures allow technicians to easily assess key features such as dimensions, surface finish, and overall integrity. This helps to quickly identify any defects or irregularities in the formed parts before they reach the final assembly stage. Check out Tooling Technologies’ capabilities to learn more!

Fill out the form for more information and we will get back to you.